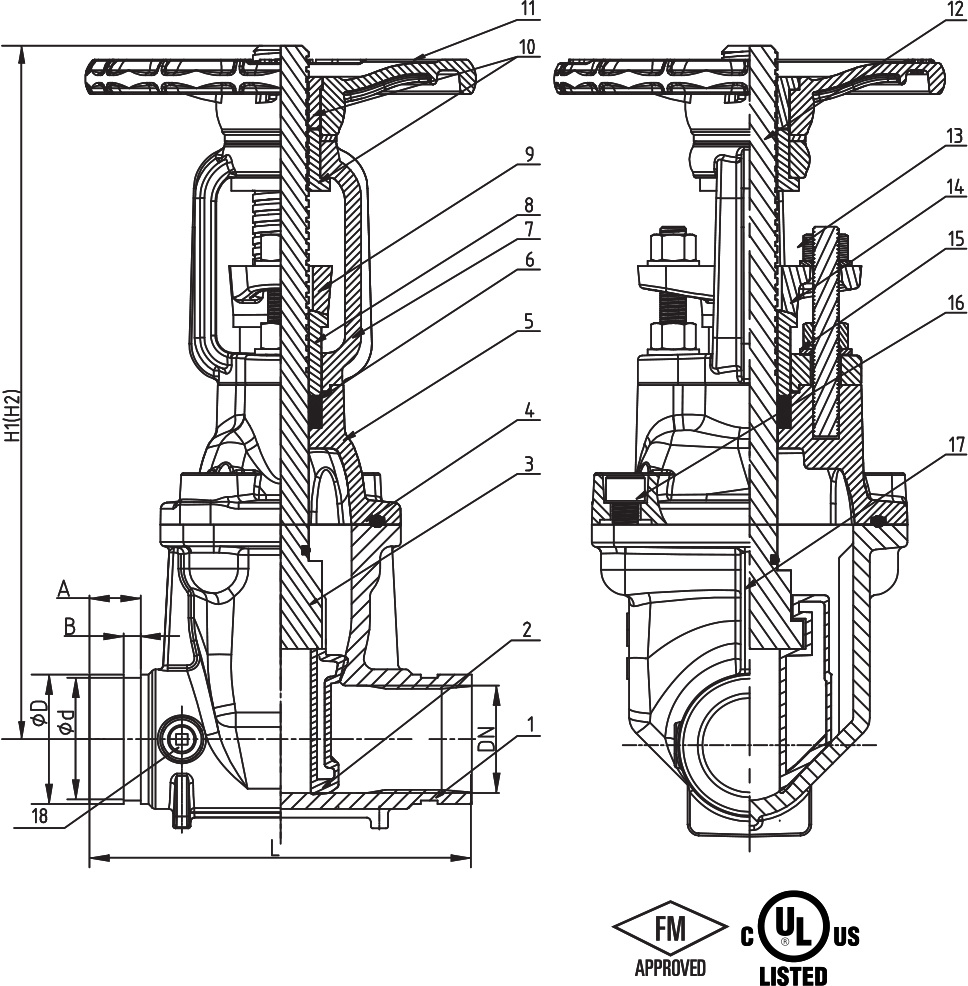

Outside Screw and Yoke (OS&Y) Gate Valve - Grooved

OSG

Technical Features

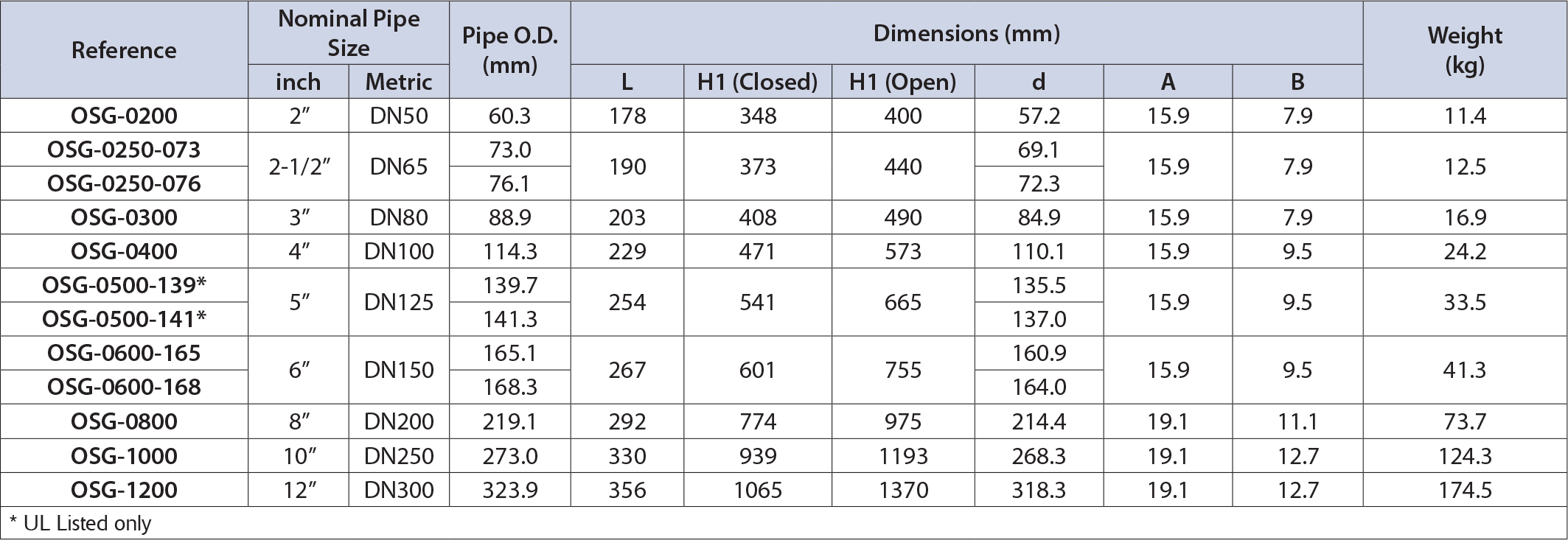

- Sizes available (Nominal) : 2”/DN50, 2-1/2”/DN65, 3”/DN80, 4”/DN100, 5”/DN125, 6”/DN150, 8”/DN200, 10”/DN250 and 12”/DN300

- Working pressure :21 bar (300 psi)

- Seat Type: Resilent wedge

- Finish :Fusion bonded expoxy coating internal and external

- Connections : Grooved metric or AWWA C606 standard

- Specification : Design and dimensions conform to AWWA C515

- Features : Pre-notched, stainless steel stem for easy attachment of supervisory switch

- Note : Size 5” is only UL listed

Outside Screw and Yoke (OS&Y) Gate Valve - Grooved - OSG

Physical Data

Outside Screw and Yoke (OS&Y) Gate Valve - Grooved - OSG

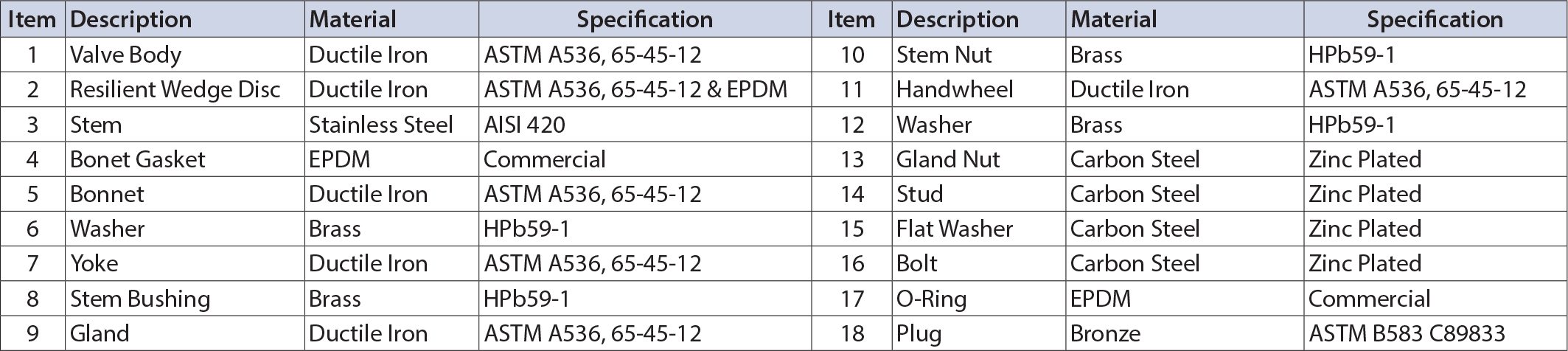

Materials List

Installation

- Piping systems and valves should be thoroughly cleaned and free from ingress of foreign materials.

- Visually inspect the valve seating and ports for cleanliness immediately prior to installation.

- All valves should be independently supported against movement and stress from the connected piping system.

- Ensure that the valve pressure rating is compatible with service conditions.

- Operate the valve at least once from the open to closed position.

- Verify that packing nuts are tight before pressurizing the system.

- Gate valves are not suitable for throttling applications.

- Gate valves should be installed in the vertical position on horizontal pipework and in the horizontal position on vertical pipework.

Inspection and Maintenance

- Valves should be inspected periodically and should be cycled to prevent buildup of foreign materials in the piping system and valve body.

- In the event of a packing leak adjust the packing nuts to increase pressure on the stem packing. Packing nuts should be tightening evenly approximately a quarter turn in a clockwise direction.

- Always shut down the system before repacking the valve. Valves are designed with backseats for repacking under pressure but this is not recommended.

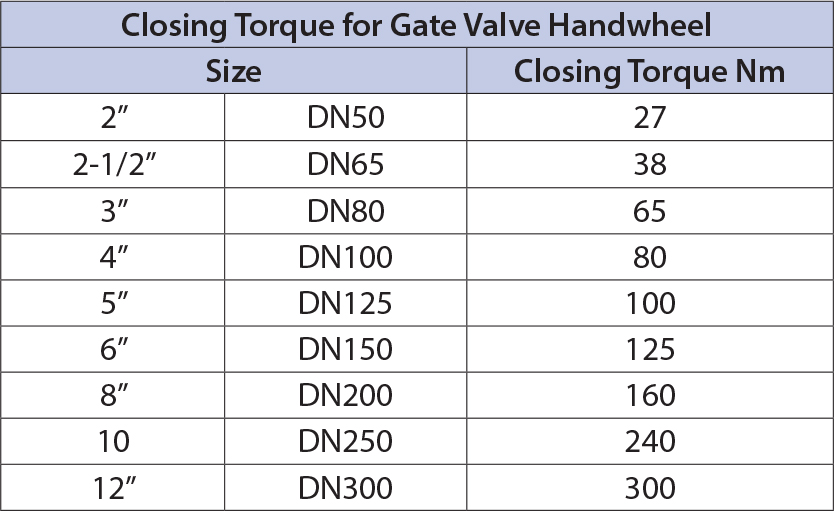

Operation

Gate valves are manually operated multi-turn valves and are opened by a handwheel or other operating device, generally in a counter clockwise direction and then closed clockwise.