Carbon Dioxide Extinguishing Systems

Fighting Fire with CO2

Extinguishing fires quickly and effectively

No extinguishant residues

Quick and effective fire-fighting is the strong point of carbon dioxide extinguishing systems. Extinguishing with carbon dioxide is achieved by displacing the oxygen from a fire source quickly - and thus starving the fire. The high heat binding capacity of the carbon dioxide causes the withdrawal of energy from the source of the fire, which enhances the extinguishing effect.

Only possible with carbon dioxide

Carbon dioxide extinguishing systems are especially wellsuited for high risk areas, where, in the event of a fire, it is necessary to keep the protected objects available and functioning, to minimize operational interruptions after a fire, to prevent reactions between the burnt material and the extinguishing agent, to prevent damage from the extinguishing agent itself and to ensure effective extinguishing of objects in areas with difficult access (3-D extinguishing effect).

Carbon dioxide extinguishing systems, due to their special extinguishing agent properties, feature advantages over other inert gas extinguishing systems: Even freestanding objects in a room can be protected. The liquefied carbon dioxide forms a thick aerosol cloud in the flooding zone. Special local application nozzles put the extinguishing agent precisely at the object to be protected.

Safe is better

The extinguishing process with carbon dioxide reduces the oxygen in the air in the protected zone significantly below the natural level of 21 percent by volume. Carbon dioxide in concentrations that can extinguish fires can be harmful to life, and therefore special safety measures are installed.

The extinguishing process will not start until after a predetermined warning time, so that there is sufficient time to leave the room. All warning components are provided two-fold and are connected to different power sources.

Optimized and individually customized

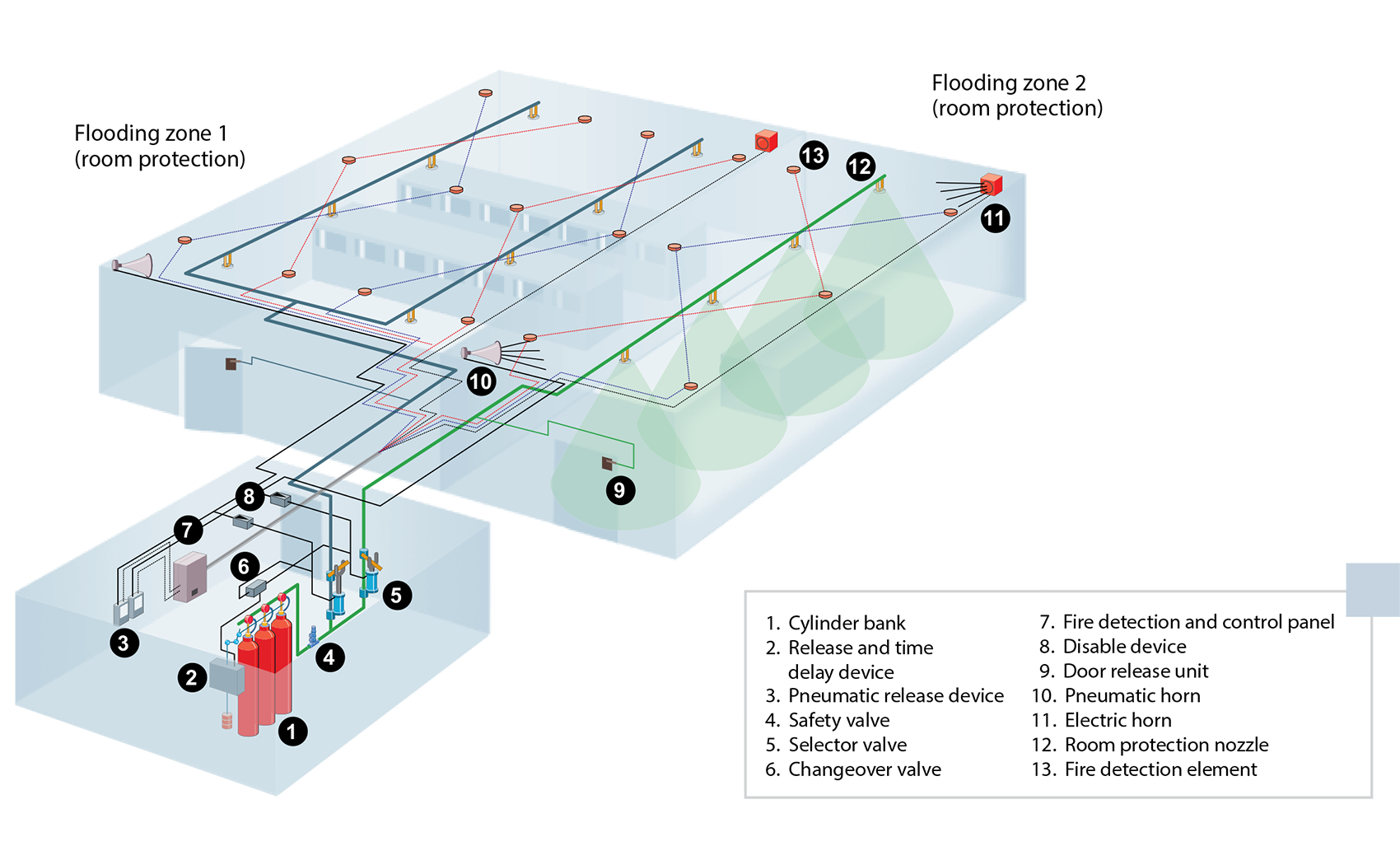

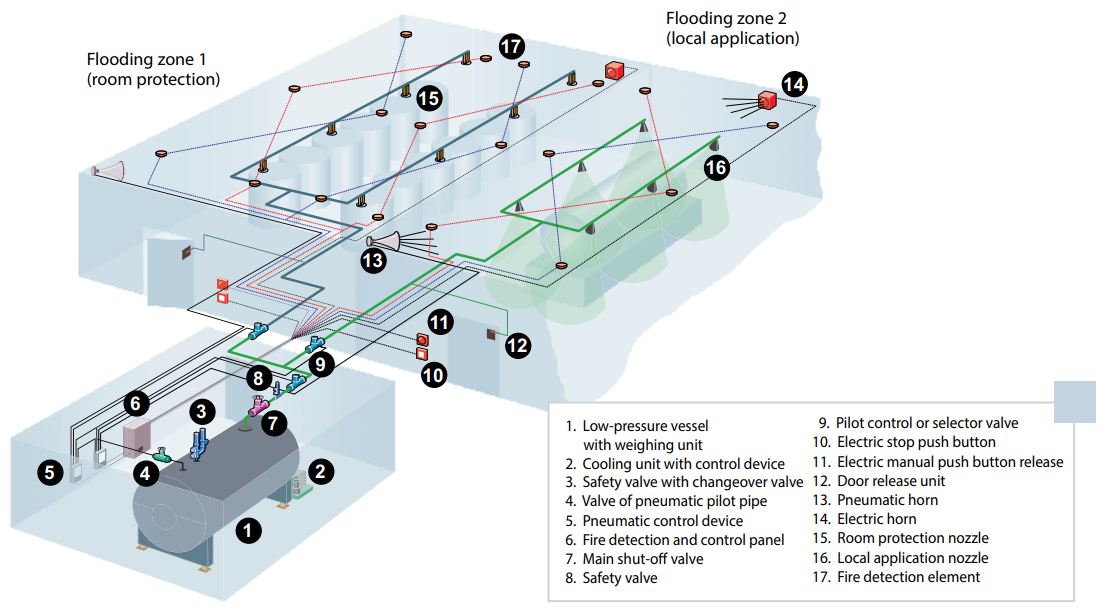

The required quantity of extinguishing agent depends on the volume and surface of the protection zone, the quality (e.g. gas impermeability) and the type of assets to be protected. The size of the pipe network and the location of the extinguishing nozzles are based on the risk area, while the extinguishing nozzles themselves are evenly distributed throughout the entire flooding zone.

For the protection of special facilities, the nozzles are installed directly within the object, such as in electric switching cabinets, false floors for cables or machine tools. If several flooding zones are connected to a common extinguishing agent supply, the gas is released for each zone via selector valves.

Structure and function

Safe and flexible

The carbon dioxide is supplied in high-pressure cylinders or low-pressure vessels. The optimum supply method depends on the quantity of gas required and the individual situation.

Supply of extinguishing agent in high-pressure steel cylinders

The high-pressure steel cylinders are consolidated into one

cylinder bank at the installation location in special frames

with independent suspension. Arranged in one or more rows,

surprisingly large supplies of gas can be stored in a very

small space.

The high-pressure steel cylinders are consolidated into one

cylinder bank at the installation location in special frames

with independent suspension. Arranged in one or more rows,

surprisingly large supplies of gas can be stored in a very

small space.

The special frames can easily be adapted for extended protection zones or quick replacement of individual cylinders. Each cylinder suspension is also a weighing unit, which automatically indicates minimal leakage of extinguishing agent.

Functional readiness and operational safety

Neuralgic functions and components of the extinguishing system, such as the gas quantity, shutoff, release and distribution units, are monitored to ensure the constant functional readiness of the extinguishing system.

Supply of gas in low-pressure vessels

If large quantities of extinguishing agent are needed for the

overall safety concept, a low-pressure vessel is recommended

– especially on grounds of economy. The liquefied carbon

dioxide is stored in this vessel at a temperate of approx. –20 °C

and at an operating pressure of approx. 20 bar. A cooling

unit provides a constant low temperature. The operating costs

are minimized by an optimum insulation design.

If large quantities of extinguishing agent are needed for the

overall safety concept, a low-pressure vessel is recommended

– especially on grounds of economy. The liquefied carbon

dioxide is stored in this vessel at a temperate of approx. –20 °C

and at an operating pressure of approx. 20 bar. A cooling

unit provides a constant low temperature. The operating costs

are minimized by an optimum insulation design.

The supply vessel is mounted on a calibratable electronic weighing unit, which constantly displays the actual weight and therefore any potential loss of gas due to leaks.

Danger detected

The control and monitoring of the carbon dioxide extinguishing systems is provided by the Viking fire detection system. Fire detectors monitor the protected zone. If the system detects smoke, an excessive rise in temperature or flames, the fire detection control panel initiates the extinguishing process.

Compact assembling groups

Pre-fabricated for equipment protection

In pre-fabricated compact modules, all function-relevant components are combined with various functions in a single unit and accommodated in a protective cabinet, where they are protected from dust, moisture and mechanical damage. A compact module consists of a frame with freely suspended extinguishing gas cylinders, which are connected via pressure-proof hoses with the manifold, including weighing units with electronically monitored leakage indicators and an electromagnetic gas release.

A fire detection control panel integrated in the front door is connected to the detectors, which react to heat or smoke, and activates the extinguishing unit in the event of a fire.

The Viking compact module can be placed in the immediate vicinity of the object to be protected and can quickly be connected with the cable and pipe network using standard connections.

The high degree of pre-fabrication and the simple and fast installation make the Viking compact module an interesting and cost effective alternative to conventional systems for many objects, such as machine tools, switching cabinets or server cabinets.

Applications

A class on its own

Due to its outstanding properties, the carbon dioxide extinguishing system is the ideal fire protection solution for many areas of application.

Typical areas of application for the carbon dioxide extinguishing system are:

- Rolling mills

- Turbines

- Transformers and substations

- Warehouses for hazardous materials

- Machine tools and special metal processing systems

- Paint and varnish manufacturing and processing areas

- Painting and powder coating booths (ESTA)

- Hydraulic systems

- False floors and cable shafts

- Silos and dust filters

- Printing machines

- Engine test benches and ship engine compartments

- Switching and control systems

Benefits

At a glance

There are numerous reasons to choose a carbon dioxide extinguishing system from Viking:

- Suitable both for the protection of rooms and of free-standing objects.

- Carbon dioxide is a natural component of the ambient air and is therefore readily available.

- Extinguishes without residue and without affecting the protected objects.

- Chemical reactions as a result of extinguishing are practically impossible.

- The extinguishing agent is electrically non-conductive and is therefore suitable also for protecting electric system components.

- The homogeneous distribution of extinguishing agent and the fast concentration buildup provide for optimum effectiveness.

- After a fire, there is no extinguishing agent residue and therefore no cleanup expense.

- The extinguishing effect is ensured even at low ambient temperatures.

- Documented reliable extinguishing provides maximum protection of assets.

- The system technology for the components has been tried and tested for decades.

- The modular, multi-zone system can easily be adapted for nearly any renovation or expansion measures.

- Carbon dioxide extinguishing systems allow particularly space-saving extinguishing agent storage, especially with low-pressure vessels.

- After a fire, the extinguishing system is soon ready for operation again, at a low cost.

- Approvals by certified test authorities and the compliance of the design with national standards ensure acceptance by insurance companies and building authorities.

- If installed, insurance companies grant rebates on fire and fire business interruption insurance.

For further information, please contact your local Viking sales office or refer to the technical documentation. The contents of this publication are subject to modifications without notice.