VSN 200 Fire Extinguishing Systems

Fighting Fire using HFC-227ea

Fire protection

Efficient and compact

VSN 200 fire extinguishing systems fight fires using HFC-227ea. This extinguishing agent is particularly suitable for the protection of spaces with electronic and electrical equipment and offers an economical fire protection solution especially for small and medium-sized rooms. The 50 bar technology of the VSN 200 system makes optimal use of the characteristics of this extinguishing agent.

The HFC-227ea extinguishing agent reduces the heat of the fire and thus stops the combustion reaction. It is very efficient yet unaggressive at the same time.

The extinguishing agent is stored as a liquid and transforms into a gas only when it exits from the extinguishing nozzles. It therefore extinguishes, as a rule, even concealed fire sources instantaneously. The rapid extinguishing of a fire already in the nascent phase minimizes the fire damage and prevents long downtimes or business interruptions.

Furthermore, - unlike the case of water, foam or powder - secondary damage caused by the extinguishing agent itself is practically impossible. HFC-227ea is neither corrosive nor electrically conductive, leaves no residue and can easily be removed from the space concerned through ventilation. HFC-227ea is, besides inert gases, the preferred extinguishing agent for electronic and electrical risks.

HFC-227ea fire extinguishing systems already achieve their extinguishing effect at a substantially lower design concentration than that of inert gas extinguishing systems. This means that in the event of fire, less extinguishing agent must be introduced, which in turn makes it possible to implement shorter flooding periods. In addition, the pressure relief valve can be made significantly smaller, in most cases.

Furthermore, the comparatively small quantity required for use is stored in liquid form. This allows for extremely compact storage of the extinguishing agent. In addition, in the design concentration of HFC-227ea does not present any health hazard, which is why VSN 200 installations are also suitable for areas that are accessed by people.

In 1992 HFC-227ea replaced halon, which had been banned in the meantime, and since then has been used in hundreds of thousands of fire extinguishing systems. It is better known under its trade names, for example FM-200® from DuPontTM.

50 bar

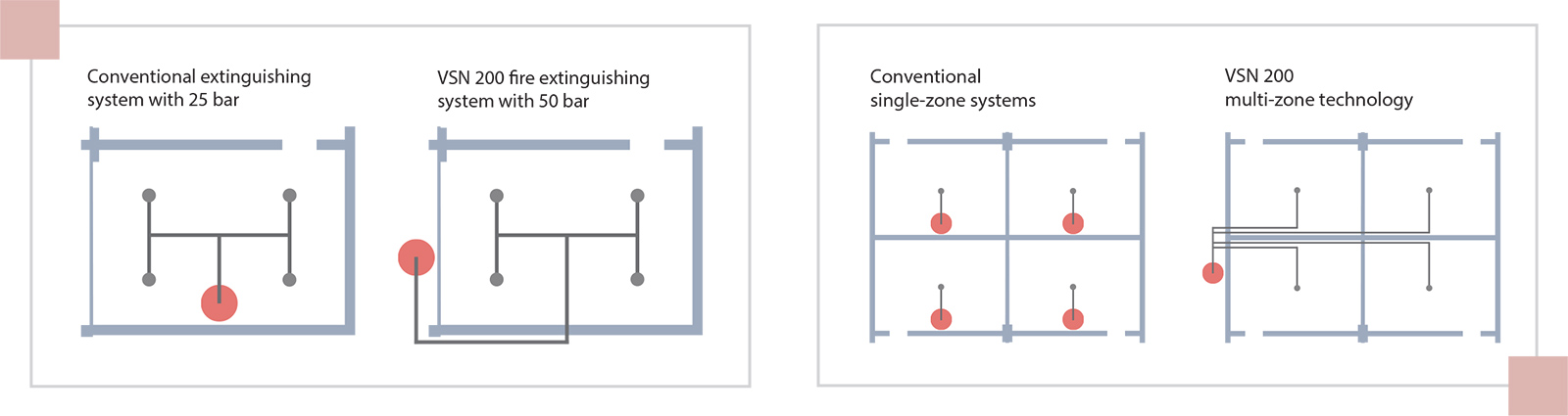

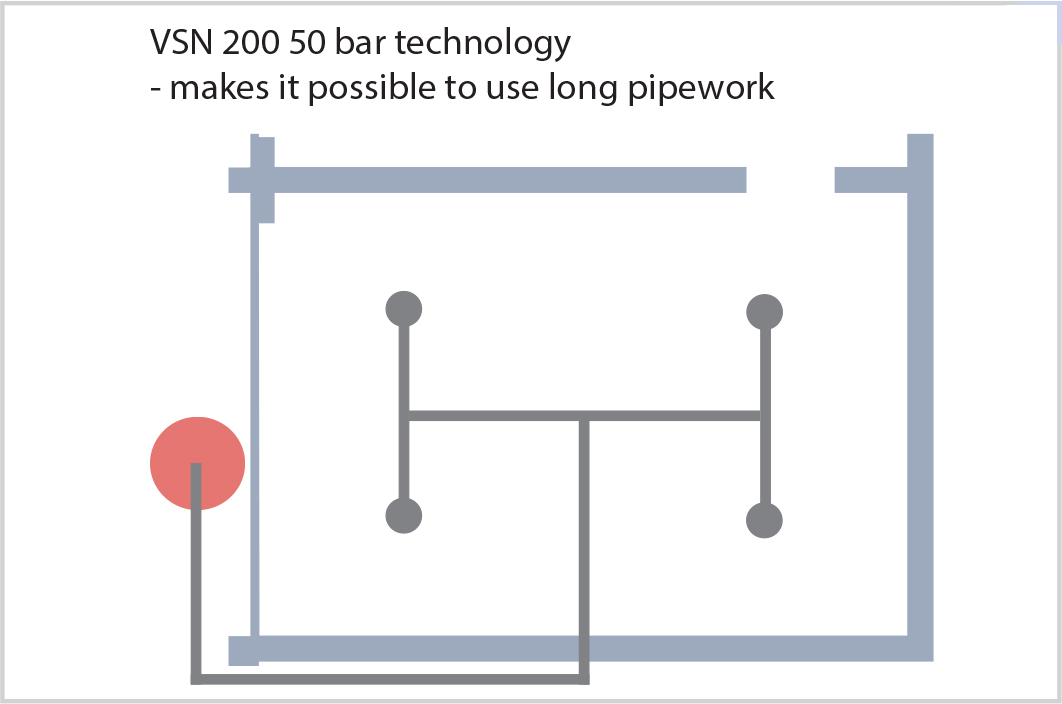

In addition to the operating pressures of conventional HFC-227ea fire extinguishing systems of 25 bar and 42 bar, VSN 200 systems are also available in a 50 bar configuration, which offers some significant advantages. For example, they can be adapted individually and tailored specifically to the requirements of the protected area.

Longer pipelines

The regulations for fire extinguishing systems using HFC-227ea require that the protected area be flooded within a maximum of 10 seconds. The 50 bar technology makes it possible to use longer and more complex piping than systems using lower operating pressures. This means that the extinguishing agent can also be stored outside the protected area

This option has the following advantages:

- In the event of fire, the extinguishing system itself is not exposed to fire.

- The space in the protected area can be used for its actual purpose, e.g. for additional server cabinets in the server room.

- The stock of extinguishing agent can be serviced quickly and easily without having to enter sensitive areas.

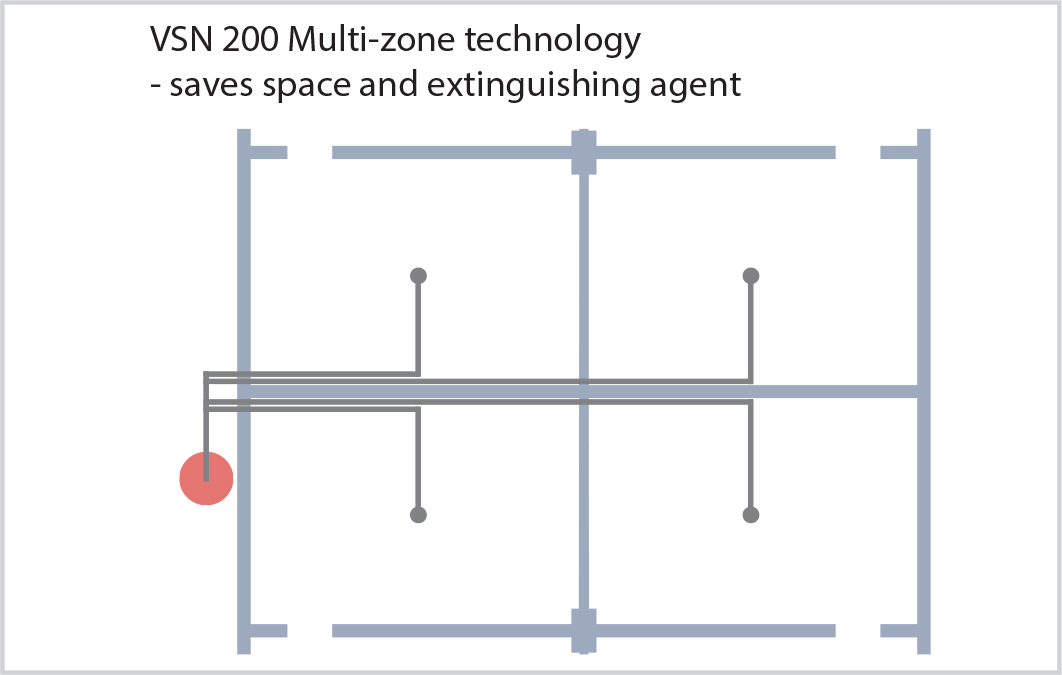

Multi-zone systems

With 50 bar technology, it is possible to set up one multi-zone system instead of several single-zone systems. Multi-zone systems jointly use a single stock of extinguishing agent for all rooms, while in the case of single-zone systems, a separate storage facility must be provided for each room. This reduces costs and saves space, especially if several rooms of a similar dimension have to be protected in a building.

Structure and function

VSN 200 fire extinguishing systems can be designed for use as a single-zone system to protect a single protected area or in the form of a multi-zone system to protect two or more areas.

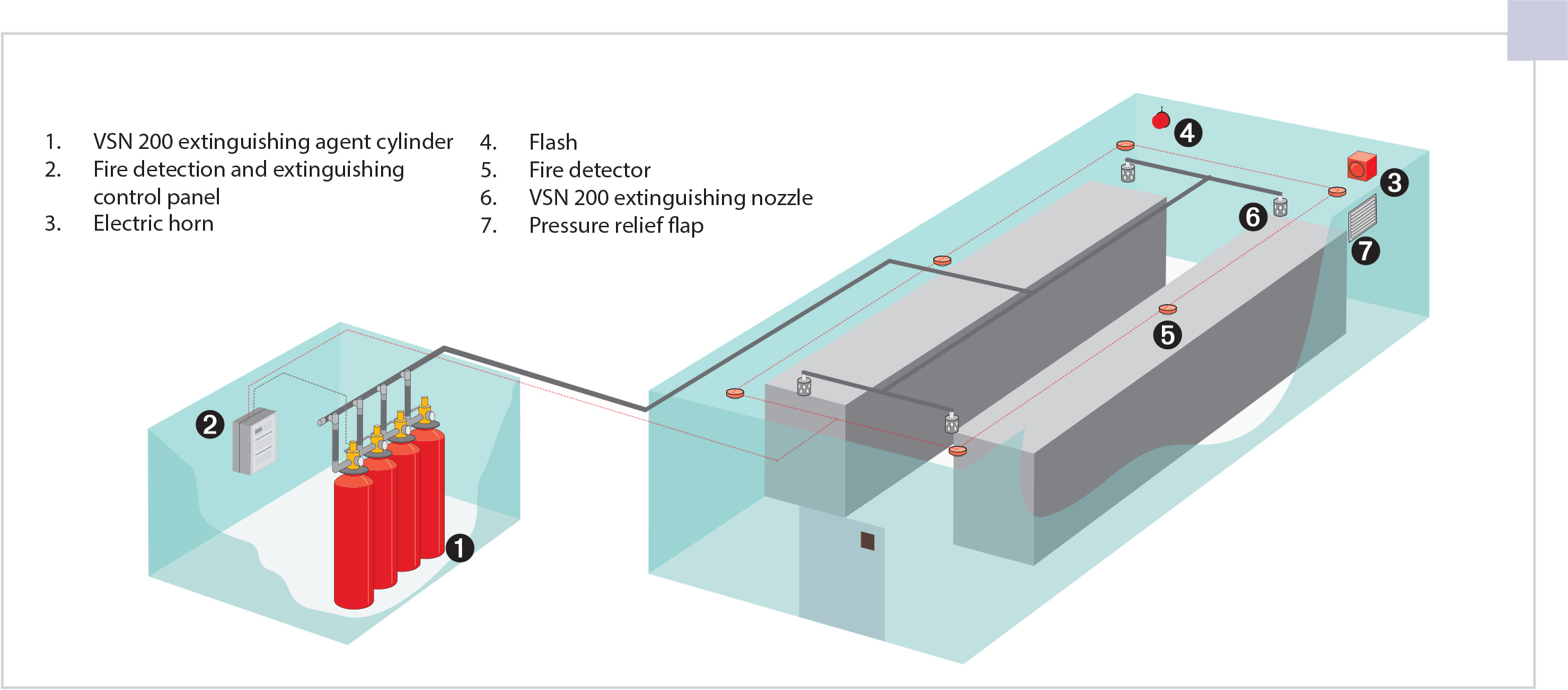

Single-zone systems

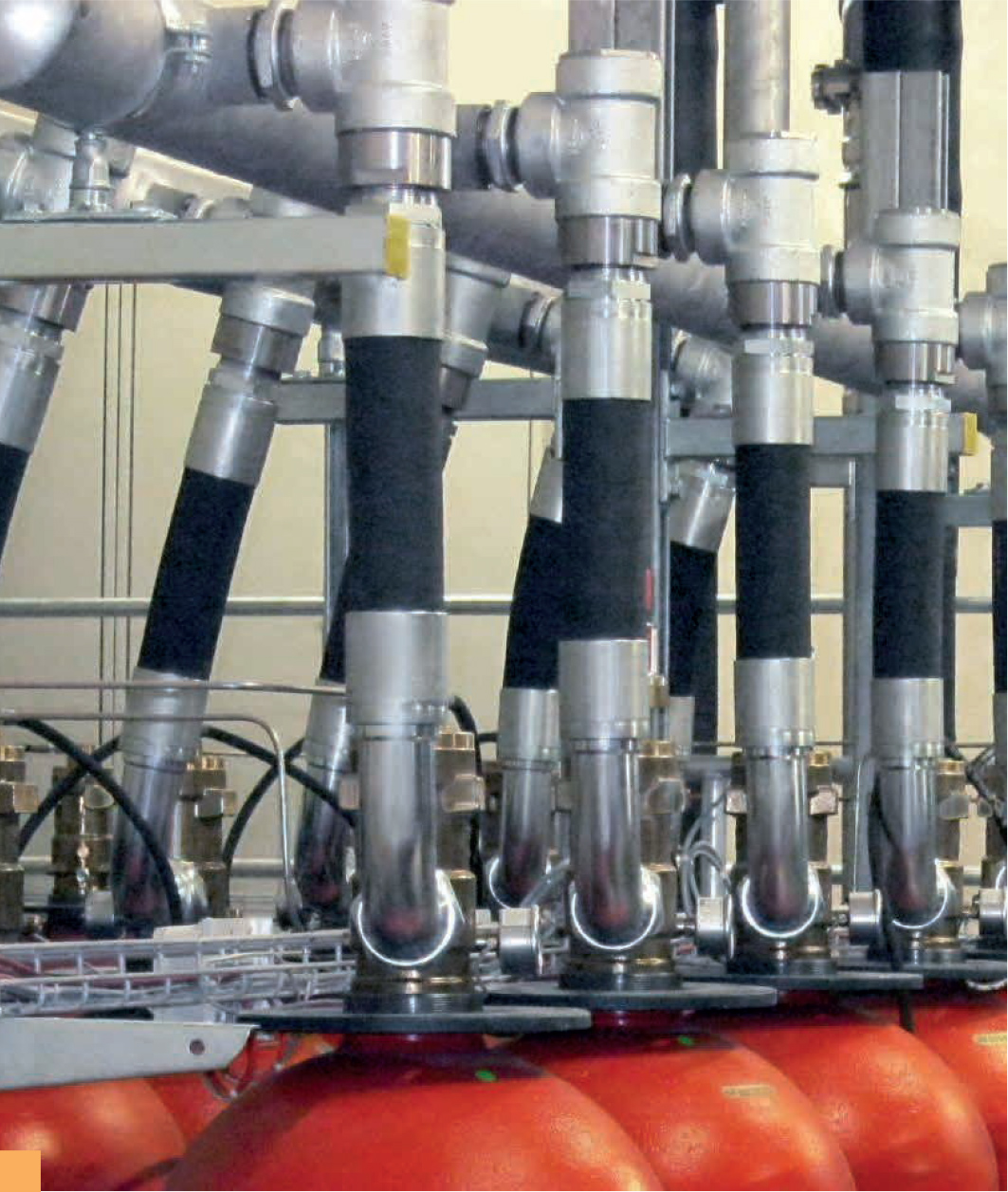

A pipework system installed with VSN 200 extinguishing

nozzles is installed in the protected space, while the dimension of the pipework, along with the number and layout of the

extinguishing nozzles, is determined by the risk concerned

and the specific local conditions. The extinguishing agent is

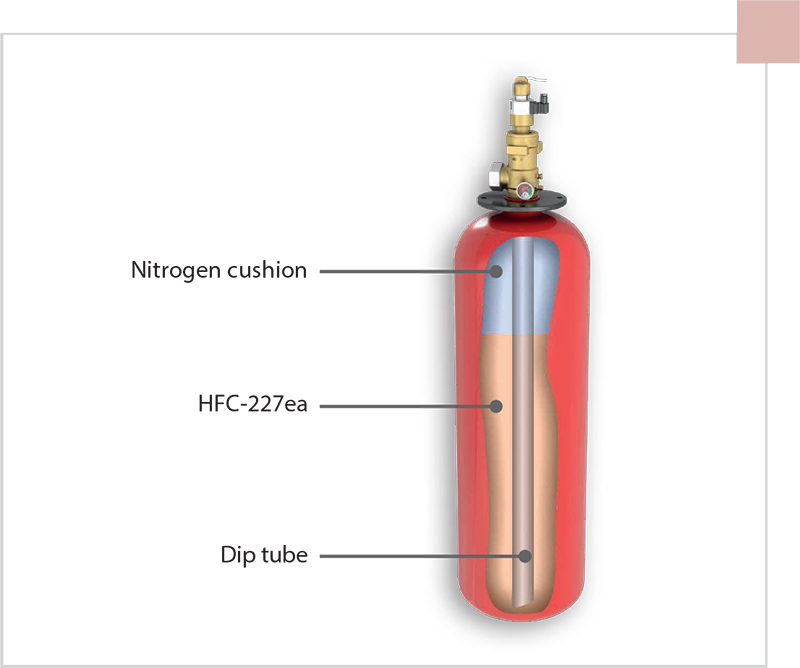

stored in liquid form in special cylinders, where a nitrogen

cushion is superimposed over the extinguishing agent and

thus generates the operating pressure of 42 or 50 bar.

A pipework system installed with VSN 200 extinguishing

nozzles is installed in the protected space, while the dimension of the pipework, along with the number and layout of the

extinguishing nozzles, is determined by the risk concerned

and the specific local conditions. The extinguishing agent is

stored in liquid form in special cylinders, where a nitrogen

cushion is superimposed over the extinguishing agent and

thus generates the operating pressure of 42 or 50 bar.

To protect smaller rooms, a single cylinder is often sufficient. Multi-cylinder systems are used to protect larger rooms.

Smoke detectors continuously monitor the extinguishing zone and send a signal to the fire detection and extinguishing control panel in the event of a fire. In the case of single-cylinder systems, the control panel then opens the electrical valve of the extinguishing agent cylinder to release the agent into the pipework. In the case of multi-cylinder systems, the first cylinder is electrically activated and through the nitrogen cushion in this first cylinder, the other cylinders are triggered pneumatically. At the same time the fire detection and extinguishing control panel triggers an audible and visual alarm, whereby persons present will be asked to leave the room.At the same time, it transmits a signal to a permanently manned station. After expiry of a predetermined warning time, the extinguishing process starts: The extinguishing agent is carried through the pipework into the extinguishing zone within 10 seconds.

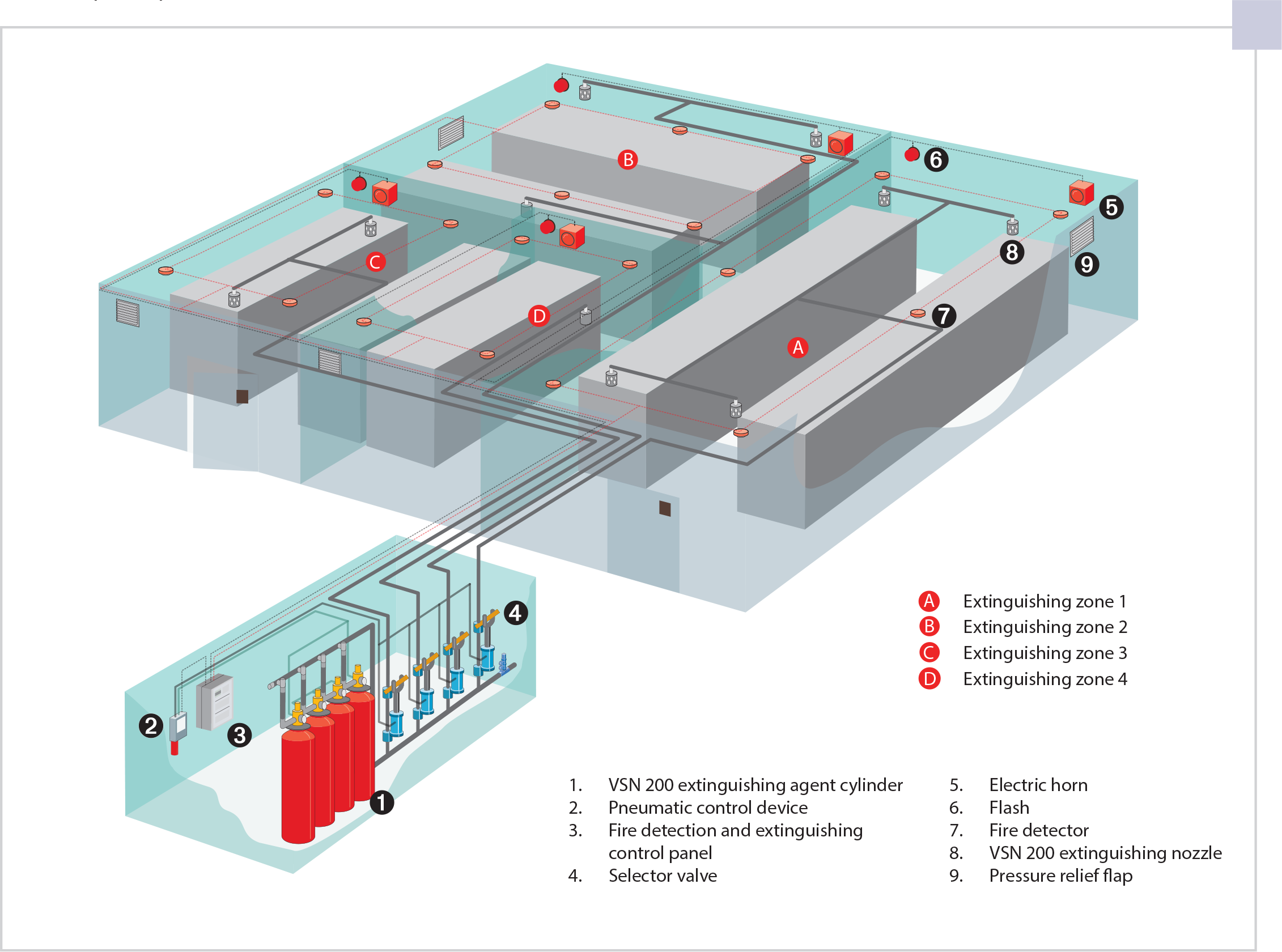

Multi-zone systems

Multi-zone systems are very similar to single-zone systems, except that they use a common stock of extinguishing agent to protect all rooms. In the event of a fire, the fire detection and extinguishing control panel controls specific selector valves. These valves release the extinguishing agent only into the extinguishing zones affected by the fire.

The required quantity of extinguishing agent is always calculated in relation to the largest protected space. If a smaller space is affected by the fire, only as much extinguishing agent as is required is released to extinguish the fire in this space. Due to the reserve of extinguishing agent, the fire extinguishing capacity of the system is guaranteed even after the extinguishing system has been triggered - providing continuous, uninterrupted operation.

Fire detection and extinguishing control technology

The control and function monitoring capacity of VSN 200 fire extinguishing systems should be provided ideally by the tried and tested Viking FMZ 5000 detection alarm and extinguishing control technology. This ensures optimal compatibility – supported by relevant certifications – of electrical and mechanical system components and avoids unnecessary coordination expense and interface problems between different system parts.

Optimal Design

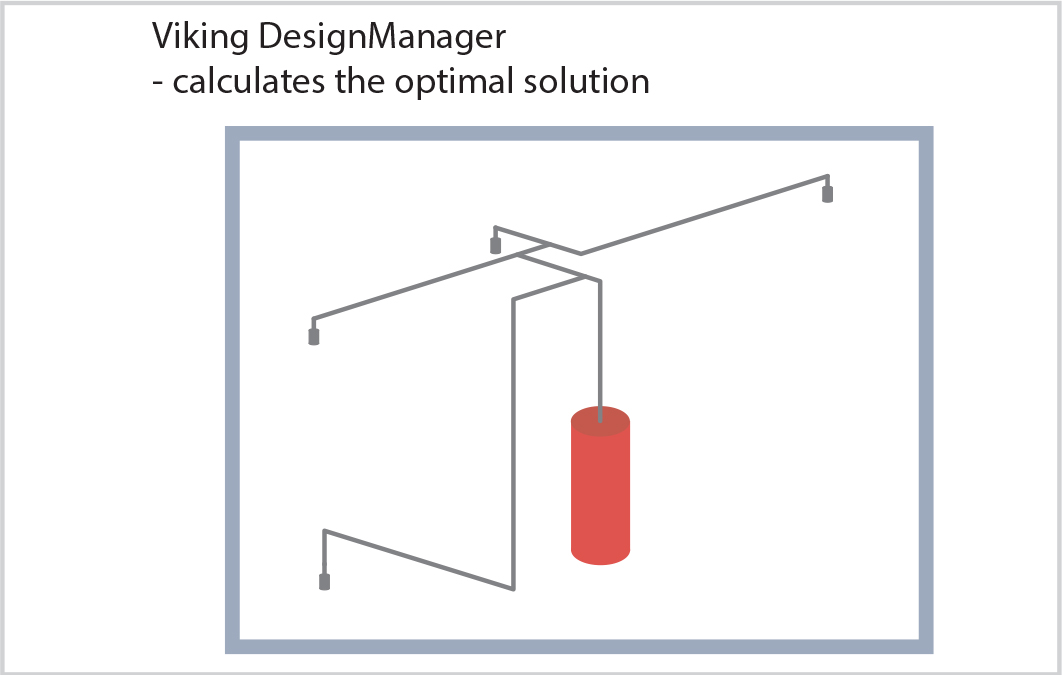

Viking Design Manager

In the pipework, a two-phase flow - composed of liquid

HFC-227ea and gaseous nitrogen – is generated after activation of the extinguishing system; this presents a particular

challenge for the hydraulic calculation when planning

the system.

In the pipework, a two-phase flow - composed of liquid

HFC-227ea and gaseous nitrogen – is generated after activation of the extinguishing system; this presents a particular

challenge for the hydraulic calculation when planning

the system.

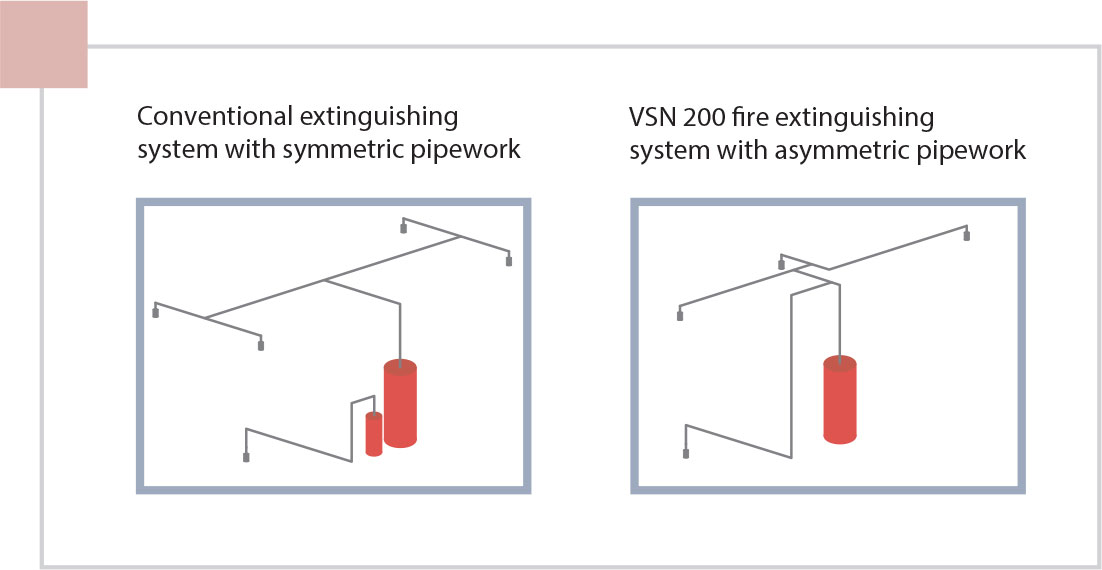

VSN 200 fire extinguishing systems are designed for specific projects with the Viking DesignManager. This design programme is based on a specially developed simulation model for the two-phase flow, which has been verified in numerous flow tests on extinguishing system models.

Thanks to the calculation accuracy of the Viking DesignManager, extinguishing systems can be optimally designed - both as regards safety systems and from an economic perspective: the designed extinguishing systems have been proven to be dependable and effective. Unlike conventional design programmes, the Viking DesignManager is also able to calculate complex and asymmetric pipework, thus offering more flexibility in the system design.

Whether a 50 bar or 25 bar system, symmetric or asymmetric pipework – Viking DesignManager will always find the ideal system version and solution for each project. To further ensure safety in the design of the system, the guided menu of the Viking DesignManager is designed so as to perform an error and plausibility check even while the basic data are entered into the system.

Another highlight: An interface to the AutoCAD software integrated into the Viking DesignManager offers a convenient design of the installation and makes it possible to import the result into the project documents and system records afterwards.

Applications

A class on its own

VSN 200 fire extinguishing systems are particularly suitable for the protection of spaces with electrical and electronic facilities, even if people are present in the premises.

All system variants and options of the VSN 200 fire extinguishing systems are UL-listed, FM-approved and tested and certified by VdS Schadenverhütung. Approvals by other international certification bodies are also available.

Examples of use:

- Server rooms and other IT facilities

- Data archives

- Telecommunications equipment

- Control rooms and control stations

- Instrumentation and control rooms

- Electrical switch rooms

- Switchgear and distribution cabinets

Benefits

There are many reasons for choosing a Viking VSN 200 fire extinguishing system:

- The systems provide an excellent extinguishing effect in rooms with electronic and electrical equipment.

- The HFC-227ea extinguishing agent is neither corrosive nor electrically conductive, leaves no residue and can easily be removed from the space in question through ventilation.

- The HFC-227ea extinguishing agent is also very suitable for zones that are frequented by people and has no ozone depletion potential.

- Operating pressures up to 50 bar allow for more extensive pipework and storage of the extinguishing agent outside the protected area.

- Through cost-effective multi-zone systems, a single stock of extinguishing agent is sufficient to cover several zones.

- The Viking DesignManager calculates complex, asymmetrical pipework automatically and delivers optimal solutions - both from a safetyrelated and an economic perspective.

For further information, please contact your local Viking sales office or refer to the technical documentation. The contents of this publication are subject to modifications without notice.